Anodizing is a commonly used surface treatment process, especially playing a key role in the manufacturing of aluminum alloy casings for smart products. This article will discuss the importance of anodizing in aluminum alloy smart products, and specifically list the anodizing requirements for the metal shells of eight smart products: laptops, handheld computers, keyboards, smart wearables, portable speakers, decoders, and submarines. Notes, case descriptions, and data substantiation.

Basic introduction to anodizing process

Anodizing is a process that forms an oxide layer on the metal surface. By controlling the formation of the oxide layer, aluminum alloy products can be given excellent properties, including corrosion resistance, wear resistance, and improved surface finish. In aluminum alloy smart products, anodizing can not only improve the appearance and texture of the product, but also enhance the durability and stability of the product, thereby improving user experience and product quality.

7 Brand Cases

1. Laptop

HUAWEI

Reasons for application: Most of our laptop customers use lightweight aluminum alloy 6061 casings. The anodized laptops are more wear-resistant, scratch-resistant and corrosion-resistant to protect the laptop surface from daily use. Friction and wear.

Process notes: During the anodizing process, process parameters need to be controlled to ensure uniform thickness and consistent color of the surface oxide layer to avoid uniformity problems. The thick film of our notebook computer is basically maintained at a thickness of 18-25 microns.

Customer case: Huawei laptops use anodizing technology during the production process, which improves the texture and durability of the product appearance, winning the favor of consumers.

2.Handheld console

GPD

Reasons for application: With the rise of game enthusiasts, portable and easy-to-operate handheld consoles require manual polishing process combined with anodizing process. They are light and drop-resistant and smoother at the same time. The silky operating feel brings better comfort to users. experience

Process notes: Sometimes the electropolishing process cannot fully meet the ergonomic requirements, so manual polishing and inspection followed by anodizing can achieve the ideal appearance.

Customer case: GPD is currently one of our largest customers. Each new product adopts leading and market-standard process requirements, winning the following of many consumers.

3.Keyboard

KBDfans

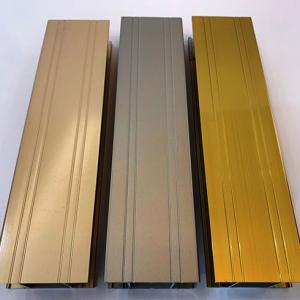

Reasons for application: Keyboards are usually products that office workers get along with day and night. The new generation of young consumer groups pursue keyboards with diversified colors and smooth and beautiful appearance designs. The use of anodizing can give the keyboard rich colors.

Process notes: When processing the keyboard surface and bottom case, attention must be paid to protecting the keycaps and key structure to avoid surface treatment affecting the sensitivity and service life of the keys.

Customer case: Most of the aluminum alloy shells of KBDfans keyboard brand adopt high-quality anodizing process, which improves the overall quality and service life of keyboard products.

4. Smart wear

Xiaotiancai

Reasons for application: Since smart wearable products are worn by users, contact and friction are inevitable. Therefore, the dense layer formed by anodization can be very scratch-resistant and wear-resistant. At the same time, the color of the oxide layer must be customizable to meet the aesthetic needs of different users.

Process notes: The appropriate anodizing process should be selected based on the size, model and special functional requirements of the smart wearable device to avoid affecting the signal transmission and user experience of the device.

Customer case: Xiaotiancai smart watch adopts high-quality anodizing treatment, which not only improves the appearance and texture of the product, but also enhances the durability of the product, making it highly favored by consumers.

5. Portable speakers

FIIO

Reasons for application: With the rise of lightweight outdoor travel or hiking activities, portable speakers are increasingly occupying a market. When used in outdoor scenes, the casing must have good corrosion resistance and surface finish to maintain a clear appearance and extend the service life of the speaker.

Process notes: When processing the metal casing of the speaker, care must be taken to protect the internal electronic components of the speaker to prevent the anodizing liquid from penetrating and affecting the function of the speaker.

Customer case: FIIO audio brand, which we have cooperated with for many years, uses anodizing process when producing portable speakers, which improves the appearance, texture and durability of the product, and has won unanimous praise from users.

6.Decoder

SMSL

Reasons for application: In the eyes of avid music lovers, decoders are a must-have item for playing music. What these groups often care about most is not the price, but the performance. In addition to being picky about the internal electronic components, music lovers are also extremely picky about the color and materials of the decoder. They believe that different materials determine the key to sound quality! In order to ensure the stable operation of the decoder equipment and extend its service life, the anodized aluminum alloy can better meet the cost performance of some groups while ensuring the sound quality.

Process notes: When processing the decoder casing, the thickness and uniformity of the oxide layer need to be controlled to avoid quality problems such as oxygen leakage and insufficient oxidation.

Customer case: SMSL is a company specializing in the production of high-end audio decoders. The anodizing process is used in the casing treatment of its products, which improves the overall performance and quality of the product.

7. Submersible Drone

QiYuan

Reasons for application: Submersible drones usually need to operate in the deep sea, so waterproofing and seawater corrosion resistance are particularly important. Anodizing of metal shells can simultaneously solve the needs of waterproofing and seawater corrosion resistance. Our customers generally require an oxide film thickness of more than 60 microns and a waterproofing level of IP68!

Process notes: When processing the metal shell of a diving drone, a special anodizing process is required to ensure the stability and durability of the oxide layer.

Customer case: Qiyuan, a diving drone brand listed in China, is one of our customers. Professional anodizing technology is used in the complete shell treatment of the diving drone, which improves the corrosion resistance and service life of the submarine.

Data confirmation

According to our customer feedback, anodized aluminum alloy products perform better in terms of wear resistance, corrosion resistance and surface finish, have a longer service life and are better users than untreated products. experience. It can roughly reduce the return rate by 25%, and the repair rate is reduced to 8%. Consumers have more trust and desire to purchase anodized products, thus promoting the widespread application of anodizing technology in the manufacturing of aluminum alloy smart products.

In summary, anodization, as an important surface treatment process, plays an important role in the manufacturing of aluminum alloy smart products. It not only improves the appearance and texture of the product, but also enhances the performance and durability of the product. With the continuous advancement of technology and the increase of market demand, anodizing technology will continue to play an important role in the smart product industry, bringing users a better product experience. This is why these eight major brands use aluminum alloy anodizing process. !