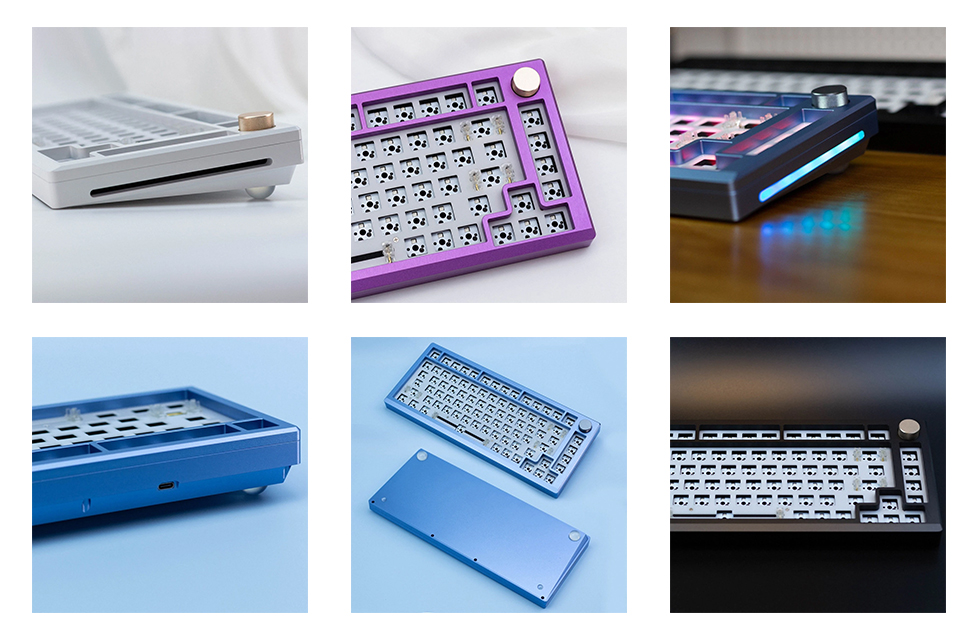

The estimation of CNC machining costs needs to take into account many factors, such as material cost, machine equipment usage time, tool wear, labor cost, etc. The following is the general CNC machining cost estimation method:

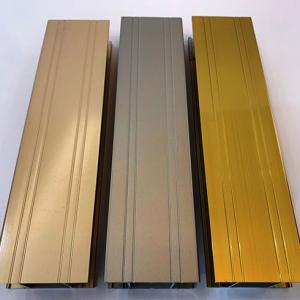

1. Material cost

The cost of processing materials is directly related to the cost of CNC processing. Product volume, the type and density of materials used in the product are directly related to the material cost. Generally speaking, the processing of high-cost materials is usually more time-consuming and complex. When calculating the material cost, the quantity of materials required and the sample price given by the manufacturer should also be taken into account.

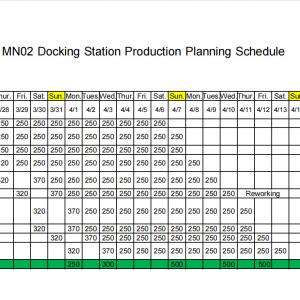

2. Machine usage time

The running time of the CNC machine directly affects the cost calculation. When estimating CNC processing costs, it is necessary to calculate in detail the time used for each machine and other influencing factors such as tool changes, optional fixtures and the number of processes, so as to calculate the total working time and cost of the CNC machine.

3. Tool consumption

The life of the cutting tools used is closely related to cutting conditions (such as speed, feed, etc.). Tools that wear out quickly need to be replaced more frequently, which increases the cost of CNC machining. Therefore, when calculating CNC machining costs, the cost of tool wear also needs to be considered. For some more expensive cutting tools or complex tools (such as boring tools), the wear cost is higher.

4. Labor costs

CNC processing requires well-trained and experienced professional workers to complete it smoothly. When calculating CNC machining costs, labor costs, including hidden costs such as training and quality control, need to be taken into account.

When estimating CNC machining costs, the above factors are only for reference. Various factors should also be flexibly adjusted according to the actual situation, so as to be more in line with the preset goals.

Finally, some suggestions are provided, that is, CNC processing costs can be controlled by improving production efficiency, reducing material costs, and using independently developed modular equipment.